For over a century, the global energy framework operated on a simple model: big power plants generated electricity exactly when people needed it. Because we couldn’t store power, everything had to be perfectly balanced in real-time. Today, that old system is changing. As we switch to a modern, decentralized grid, we can no longer rely on those old machines for stability, making battery energy storage systems essential to keep the lights on.

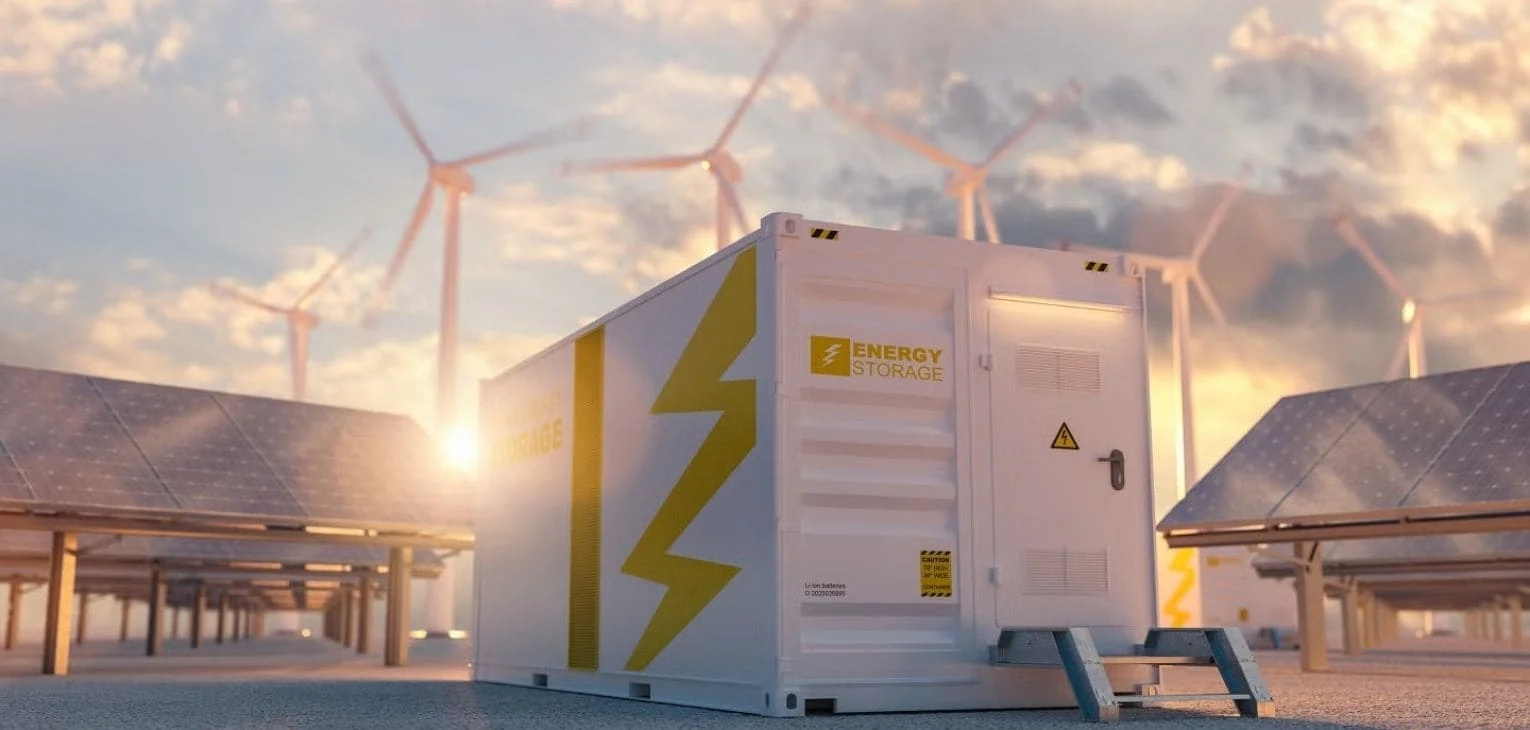

The solution (and the defining asset of this decade) is the battery energy storage system (BESS). Many people see them as just “warehouses for electricity,” but they are much more than that. A BESS battery is actually a sophisticated digital-to-chemical conversion engine. These systems provide the agility required to manage a grid that no longer relies on predictable fuel, but on the shifting patterns of the natural world. Integrating power storage technology allows us to bridge the gap between generation and demand.

By using a combination of hardware (BMS, PCS) and AI-driven software, a BESS balances grid frequency, manages peak demand, and generates revenue through market arbitrage. As the energy transition accelerates, BESS has become the essential tool for maintaining a stable, decarbonized, and high-performance power grid.

What is a Battery Energy Storage System (BESS)?

A Battery Energy Storage System (BESS) is a technology that stores electricity from the grid or renewable sources and releases it later to balance supply and demand.

By integrating batteries, inverters, and intelligent software, a BESS provides grid stability, frequency control, and cost optimization.

Unlike high-speed discharge components like capacitors, a BESS is engineered for endurance and high-volume throughput. It serves as a critical “temporal buffer,” effectively unlinking the timing of power production from the moment of its actual utilization.

While the phrase “energy storage battery” is frequently used as a synonym, the term “System” highlights the true complexity of the technology. A standalone battery is merely a passive container; conversely, a BESS represents a harmonized integration of physical hardware and intelligent software logic. This digital architecture acts as the asset’s ‘command center,’ regulating the speed of energy intake and discharge to protect the power storage battery from wear and tear while maintaining perfect synchronization with the wider electrical network.

Main Classifications of Battery Energy Storage Systems (BESS)

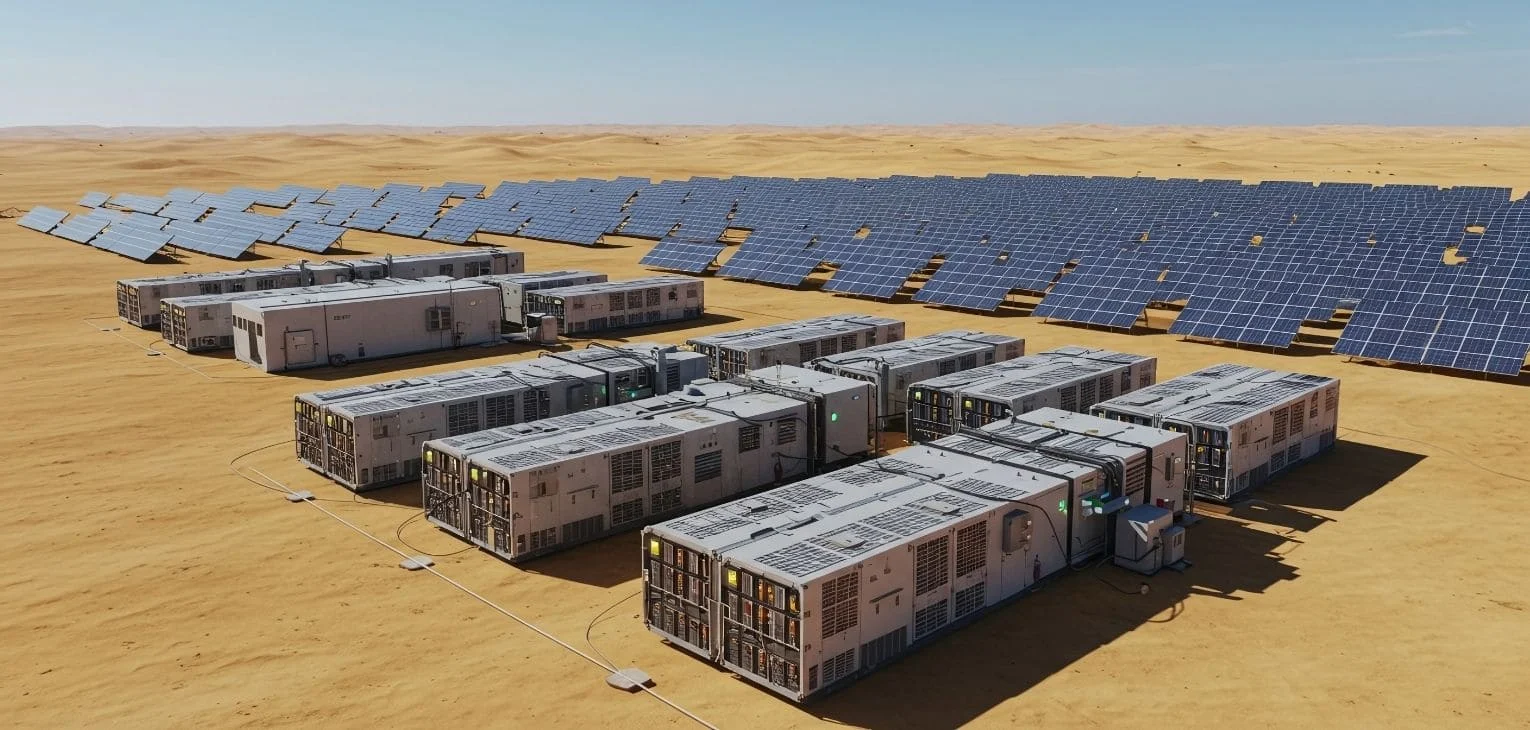

Not all BESS projects are the same. They are designed based on where they connect to the grid, how they are used, and what technology is inside. Here are the most common ways to classify these systems:

1. Grid Location: FTM and BTM

BESS are classified based on where they connect to the electrical grid and who they primarily serve.

- Front-of-the-Meter (FTM): These are large, utility-scale systems connected directly to the power grid. They help grid operators balance the energy supply for entire cities or regions.

- Behind-the-Meter (BTM): These are installed on the customer’s side (at a factory, business, or home). Their main goal is to manage local energy costs, provide backup power, and optimize solar energy use.

2. Operational Purpose

Systems are also designed based on the specific technical problem they are meant to solve:

- Power-Oriented Systems: Built for “agile” applications like frequency control and voltage regulation. They are designed to react in milliseconds.

- Energy-Oriented Systems: Optimized for long-term storage tasks like energy arbitrage (buying low, selling high) and shifting heavy energy loads to different times of the day.

3. Battery Chemistry and Technology

A BESS project is ultimately defined by its internal chemistry and cell technology. These factors shape the system’s DNA, controlling critical variables such as safety, energy density, and long-term performance retention over thousands of cycles. Main battery chemistries are:

- Lithium-Ion LFP (Lithium Iron Phosphate): This technology is used in more than 80% of large-scale storage projects today. It has a very low risk of fire and maintains its performance even after thousands of charge cycles. Since it contains no cobalt, it is the ideal solution for those looking for an eco-friendly and long-lasting investment.

- Lithium-Ion NMC (Nickel Manganese Cobalt): These can store much more energy in smaller spaces compared to LFP. While advantageous for projects with space limits, they tend to heat up more during operation and require advanced, high-precision cooling systems.

- Vanadium Redox Flow Batteries: Unlike traditional batteries, these store energy in massive liquid tanks. Their biggest advantage is providing continuous power for 10 to 12 hours. They do not lose capacity over a lifespan of more than 20 years, making them essential for very large utility-scale investments.

- Sodium-Ion (Na-ion): This technology uses sodium (salt), which is much more abundant and cheaper than lithium. Although it is a newer technology, it is seen as a strong rival to lithium due to its low cost and durability in cold weather conditions.

- Zinc-Based and Solid-State Technologies: These are developing technologies that do not contain flammable materials. They are often preferred in urban areas or buildings where fire safety is the highest priority.

4. Service and Discharge Duration

This defines how long the system can provide its full energy capacity:

- Short-Duration: Usually designed for 30 minutes to 2 hours of storage. These are used for fast grid stabilization and balancing services.

- Long-Duration (LDES): These systems provide 6 hours or more of discharge capacity and act as a strategic energy reserve for the power grid.

What are the Components of a Battery Energy Storage System?

A battery energy storage system consists of interconnected hardware and software subsystems that manage energy storage, safety, and grid interaction. Each component plays a vital role in transforming a chemical battery into a reliable power plant.

-

Battery System (Cells, Modules, and Racks)

This is the physical storage core of the project. Energy is stored electrochemically in individual cells, which are grouped into modules. These modules are then stacked into high-voltage racks. This hierarchical structure allows the system capacity to be scaled according to the specific needs of the grid or facility.

-

Battery Management System (BMS)

The BMS acts as the system’s security shield. It monitors cell voltage, temperature, and State of Health (SoH) with millisecond precision. By balancing the energy between cells, it prevents uneven wear and tear. In the event of a technical risk, the BMS physically isolates the system to ensure maximum safety.

-

Power Conversion System (PCS / Inverter)

Batteries operate on Direct Current (DC), while the power grid uses Alternating Current (AC). The PCS is the bidirectional bridge between these two worlds. It converts grid power for charging and transforms stored energy into high-quality AC power for discharge back into the grid at the correct frequency.

-

Energy Management System (EMS)

The EMS is the “orchestra conductor” of the BESS. It coordinates communication between all hardware components and implements operational strategies. It decides exactly when and how much power the system should provide, ensuring all assets work in perfect harmony.

-

Thermal Management (HVAC and Liquid Cooling)

Battery performance and lifespan are directly linked to temperature. Industrial-grade HVAC or liquid cooling solutions keep the cells within their ideal operating range. This prevents heat-related capacity loss and ensures the system remains efficient even under heavy loads.

-

Fire Suppression and Safety Systems

Critical for industrial safety, these systems include gas detection sensors that can identify flammable leaks instantly. Automated fire suppression, using aerosol or gas-based agents, is designed to stop potential risks at the source without damaging the electrical components.

-

Grid Connection and Protection Equipment

This is where the system physically and safely connects to the grid. It includes transformers to step up voltage, along with circuit breakers and isolators. These components protect the facility and the grid from electrical faults by isolating the system during emergencies.

-

Integration and Trading Software (Optimization Layer)

This is the commercial brain that determines the project’s return on investment. Platforms like smartPulse pull real-time market data to analyze price trends. The software optimizes charge and discharge cycles to maximize revenue from market participation and arbitrage.

| Subsystem | Primary Function | Business Impact |

|---|---|---|

| Battery System (Racks) | Energy Storage | Determines total capacity and discharge duration (MWh). |

| Battery Management System (BMS) | Safety and Balancing | Protects cell health and slows down capacity degradation. |

| Power Conversion System (PCS) / Inverter | AC/DC Conversion | Enables grid interaction and instant power output. |

| Energy Management System (EMS) | Operational Control | Coordinates all onsite components for higher efficiency. |

| Thermal Management | Climate Control | Prevents overheating and stabilizes system efficiency. |

| Fire and Safety | Risk Mitigation | Ensures facility safety and manages insurance compliance. |

| Grid Equipment | Transformation and Protection | Ensures safe physical connection to the utility network. |

| Power Trading Software | Revenue Optimization | Maximizes ROI by automating market participation. |

How Does BESS Work?

A Battery Energy Storage System (BESS) functions as a high-speed energy buffer for the electrical grid. It operates through a continuous, four-stage cycle that converts, stores, and redistributes power based on real-time demand.

-

The Capture and Conversion Phase (Charging Battery)

The cycle begins when the system receives surplus electricity from the grid or a renewable source, like a solar farm. Because the grid operates on Alternating Current (AC) but batteries can only store Direct Current (DC), the energy must be translated.

- The Power Conversion System (PCS), or bidirectional inverter, pulls AC from the grid and converts it into DC.

- This conversion happens at millisecond speeds, allowing the system to “soak up” excess power the moment it is generated.

-

The Electrochemical Storage Phase

Once converted to DC, the electricity is pushed into the battery cells. This initiates an electrochemical reaction where ions move between internal electrodes (typically through a liquid or solid electrolyte) to “park” the energy in a stable chemical state.

- While the energy is stored, the Battery Management System (BMS) acts as a digital sentry. It monitors the “health” of every cell, ensuring they stay at the correct voltage and temperature to prevent wear and tear.

- Auxiliary systems, like liquid cooling or HVAC, maintain an ideal internal climate to prevent the batteries from overheating or aging prematurely.

-

The Intelligence Layer (System Management)

The system does not just sit idle while full. The Energy Management System (EMS) (the system’s brain) continuously listens to signals from the power market and the grid operator.

- It monitors Grid Frequency: If the frequency drops (meaning there is too much demand), the EMS prepares to discharge.

- It monitors Market Prices: If prices are low, it stays in “charge” mode; if prices spike, it prepares to sell.

- It manages the State of Charge (SoC): Ensuring the battery never gets too empty or too full, which optimizes the asset’s lifespan.

-

The Dispatch and Synchronization Phase (Battery Discharging)

When the grid requires a boost or prices hit a profitable peak, the discharge cycle triggers. The chemical reaction inside the battery reverses, releasing a flow of DC power.

- The PCS converts this DC back into AC.

- Crucially, the inverter synchronizes this power perfectly with the grid’s current voltage and frequency (e.g., 50Hz or 60Hz) so it can be injected seamlessly.

- This response is nearly instantaneous, often providing full power in less than a second to stabilize the network and prevent blackouts.

Financial Benefits of Battery Energy Storage Systems

A battery energy storage system is far more than a technical asset; it is a high-performance financial instrument. Its primary economic value lies in “Value Stacking”, the ability to participate in several energy storage solutions and revenue streams simultaneously, often within the same operating hour.

This versatility allows owners to maximize the return on investment (ROI) by dynamically shifting the bess battery‘s activity to wherever it generates the most value.

-

High-Precision Grid Support (Ancillary Services)

The most profitable role for a power storage battery is providing “Frequency Response.” The electrical grid must maintain a constant frequency to function safely. If an energy power plant fails unexpectedly, the grid’s frequency can drop in seconds.

Unlike traditional gas plants that take minutes to ramp up, a bess battery can detect a shift and inject full power in less than 100 milliseconds. Grid operators pay a high premium for this millisecond-speed reliability, making it a major source of bess energy revenue.

-

Tactical Market Arbitrage

This is the classic “buy low, sell high” strategy applied to electricity. Using automated trading platforms like smartPulse, the system scans wholesale markets for price volatility.

When renewable production is high and demand is low, the power storage unit charges at a low cost. When the evening peak arrives and prices spike, the bess storage unit discharges. The “spread” between the purchase and sale price is the profit, making arbitrage a cornerstone of commercial battery storage profitability.

-

Steady Revenue: Capacity Markets and System Readiness

In many energy markets, energy storage companies can secure a predictable income stream through what is known as capacity payments. Unlike arbitrage, which depends on price fluctuations, these payments are made to the asset owner simply for ensuring that the BESS is available and ready to discharge during periods of extreme grid stress.

This “readiness” ensures that even during rare, high-demand events (such as extreme weather or the failure of a major energy power plant), the grid has enough “Resource Adequacy” to prevent blackouts.

-

Infrastructure Deferral and Cost Avoidance

Energy utility companies frequently face a multi-million dollar dilemma: a specific neighborhood or industrial zone is growing faster than the local grid can handle. Traditionally, the only solution was a “wires-and-poles” project, a capital-intensive process of digging trenches, replacing transformers, and installing higher-capacity power lines.

A battery energy storage system provides a much faster and more cost-effective “Non-Wires Alternative” (NWA). By strategically placing a bess battery at a congested substation or a stressed feeder line, utilities can manage local peaks without rebuilding the entire infrastructure.

-

Maximizing Renewable ROI

For developers of bess solar or wind energy projects, the battery prevents “curtailment”, where green energy is wasted because the grid cannot accept it. By storing that excess power and selling it later, the BESS ensures that every megawatt-hour generated by the renewable asset is eventually monetized, significantly improving the project’s overall financial performance.

How to Optimize and Automate BESS?

BESS optimization combines automation software, predictive analytics, and real-time market participation to maximize revenue and extend asset life.

To move beyond simple energy storage and enter the realm of high-performance asset management, a battery energy storage system must be treated as a dynamic digital entity. Physical hardware is only as effective as the logic driving it. By layering advanced power storage technology with intelligent software, operators can shift from reactive monitoring to proactive, automated wealth generation. Optimization and automation are the twin engines that drive the long-term profitability of any BESS.

-

Algorithmic Market Participation

Modern energy markets move at a velocity that exceeds human capability. To maximize bess energy revenue, automation software like smartPulse executes “Algorithmic Trading.”

- Automated Bidding: The system continuously analyzes the Day-Ahead and Intraday markets, submitting bids automatically to capture the best price spreads.

- Multi-Market Co-optimization: A smart BESS doesn’t just look at one market. It automatically splits its capacity (for example, using 20% for frequency response and 80% for arbitrage) to ensure every megawatt is sold to the highest bidder.

-

Predictive AI and Forecasting

True optimization requires looking into the future. By integrating Artificial Intelligence into energy storage systems, operators can anticipate market shifts before they happen.

- Price Forecasting: AI models ingest historical data, weather patterns, and grid congestion reports to predict when prices will spike. This allows the power storage battery to charge during unexpected price drops and discharge during peak volatility.

- Renewable Synchronization: For renewable energy facilities, like bess solar sites, automation software predicts cloud cover and solar output, ensuring the battery is always empty enough to capture excess solar and full enough to cover evening demand.

-

Intelligent State of Charge (SoC) Management

Automation isn’t just about selling energy; it’s about protecting the asset. Managing the “State of Charge” is critical to preventing battery aging.

- Dynamic Setpoints: Instead of charging to 100% every time, an optimized energy storage battery might only charge to 80% if the market signals suggest that the extra 20% isn’t worth the accelerated battery aging.

- Automated Balancing: The system automatically manages the “depth of discharge,” ensuring the cells stay within their ideal chemical window, which can extend the life of the electrical energy storage unit by several years.

-

Autonomous Health and Safety Monitoring

A fully automated battery energy storage system acts as its own first responder.

- Predictive Maintenance: Rather than waiting for a failure, the system uses “Digital Twin” technology to compare real-time performance against an ideal model. If a module starts to drift, the system sends an automated alert for maintenance before a breakdown occurs.

- Automated Thermal Control: To prevent premature aging, the EMS automatically ramps up liquid cooling or HVAC systems based on forecasted discharge intensity, preparing the thermal environment before the battery even begins to work.

-

Virtual Power Plant (VPP) Integration

For energy storage companies managing multiple sites, automation allows for the creation of a Virtual Power Plant.

- Fleet Automation: A central “brain” manages hundreds of separate power storage systems as if they were one giant battery. This allows small commercial battery storage units to band together and participate in large-scale utility tenders that they could never access alone.

By implementing these power storage solutions, the transition from a manual “battery in a box” to an autonomous, profit-generating energy power plant is complete. Automation doesn’t just make life easier; it is the fundamental difference between a BESS that merely survives and one that thrives in a volatile market.

Why Partner with smartPulse for BESS Operations?

While the physical battery provides the capacity, smartPulse provides the intelligence that transforms it into a high-yield financial asset. Operating a BESS in today’s volatile energy markets requires more than just a connection; it requires a level of speed, precision, and foresight that manual management cannot achieve. Working with smartPulse bridges the gap between raw hardware and market-leading profitability through five key pillars:

-

End-to-End Market Integration

Navigating the complexity of multiple energy exchanges (such as Day-Ahead, Intraday, and Ancillary Services) is a massive operational burden. smartPulse offers a unified “Super Platform” that connects your assets directly to major TSOs and power exchanges (like Nord Pool, EPEX Spot, and EPİAŞ) from a single interface. This removes the need for fragmented software and ensures your bess battery can bid into whichever market is most lucrative at that exact moment.

-

Fully Autonomous “smartBOT” Trading

Energy markets never sleep, and volatility can strike at 3:00 AM. The smartPulse smartBOTs are designed for 24/7 autonomous algorithmic trading.

- Speed: They react to price movements and grid imbalances in milliseconds, executing trades faster than any human operator.

- Accuracy: By automating the bidding process, smartPulse eliminates the risk of human error, ensuring your power storage system never misses a profitable spread or a critical grid-balancing event.

-

Advanced Digital Twin Simulations

Before committing your energy storage battery to a specific strategy, smartPulse allows you to “test-drive” your operations. Using the BESS Digital Twin, you can simulate different market scenarios using real historical data.

- Pre-Investment: Perform highly accurate feasibility studies to see how a battery would have performed under past market conditions.

- Operational Tuning: Continuously refine your charging and discharging logic to ensure you are maximizing ROI without causing unnecessary wear and tear on the cells.

-

Asset Health & Revenue Balance

Profitability is not just about the next trade; it’s about the next decade. smartPulse’s optimization engine considers the technical constraints of your hardware. By managing the State of Charge (SoC) and depth of discharge with extreme precision, the software protects the power storage battery from premature aging. This balance of “aggressive trading” and “asset preservation” ensures your BESS remains a high-performing revenue engine for its entire intended lifespan.

-

Real-Time Operational Visibility

Whether you are managing a single site or a massive portfolio of 700 MWh+, smartPulse provides a “glass-box” view of your operations. Through a centralized dashboard and a native mobile app, you can monitor everything from real-time energy throughput and cell health to live commercial performance. This level of transparency gives energy storage companies the confidence to scale their operations while maintaining total control.

Energy storage operations may seem complex, but the right technology simplifies everything. If you would like to discuss how to operate your batteries at peak efficiency with our expert team, we would be happy to introduce you to our platform.

Conclusion: The Future of Electricity is Stored

The battery energy storage system is the most versatile tool in the modern energy toolkit. It is a bridge between the physical and the digital. As the grid becomes more complex, the value of bess storage will only grow.

It is no longer an optional accessory; it is the central nervous system of a more resilient, autonomous, and cost-effective energy power storage future. By integrating robust hardware with intelligent power storage solutions, we aren’t just storing electricity; we are mastering the volatility of a new era. In the race toward a sustainable future, the winners will be those who implement the best energy storage systems and the smartest automation tools.